How to Make Chamfered Edge in Concrete

A chamfer edge on a concrete is a sloped or angled corner designed to improve the appearance of aesthetics, safety and simple removal of concrete formwork. It is practically hard to form a sharp pleasant corner and the concrete at corners is readily chipped, so providing the chamfer edge could safeguard the corner from chipping.

How to Make Chamfer Edge Concrete In practice

, 2 types of techniques are frequently used to make chamfered edge concrete,

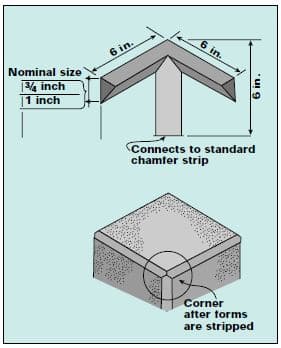

1. By using Chamfer Strips This technique of concrete edge chamfering is performed prior to concrete laying. The formwork build for the laying of concrete is fixed with the chamfer strip at the edge. Depending on the requirement of chamfered edge size,

chamfer strips are available in the sizes of 1/2, 3/4 and 1 inches. It is made of either rubber or wood.

These chamfered strips are mounted and by standard methods concrete is laid. For smooth and even finishing, concrete compaction must be assured. Formwork is slowly withdrawn after 24 hours. This technique requires no further finishing procedures.

2. Using Chamfer Edging Tools,

chamfer edging instruments are used in this technique to create chamfered edges. This is performed after the concrete has been positioned and the surface water has dried off (20 to 30 minutes after standard concrete has been positioned) unlike the above technique. The edges of the concrete are stripped off with the assistance of chamfer instruments.

2. Using Chamfer Edging Tools,

chamfer edging instruments are used in this technique to create chamfered edges. This is performed after the concrete has been positioned and the surface water has dried off (20 to 30 minutes after standard concrete has been positioned) unlike the above technique. The edges of the concrete are stripped off with the assistance of chamfer instruments.

On the concrete surface, the same sort of chamfer layout and size are acquired depending on the type of chamfered instrument used. To create this as even and smooth edge, it needs skilled labor.

Chamfer Edge making procedure 1. Allow the concrete to heal until any ground water is dissipated. This usually requires about 20 to 30 minutes after a wooden float is poured into the concrete and trowled.

2. Start by chamfering the edges of the porch with the edging tool to embed any gravel below the finished surface. Grip the handle of the instrument and insert the narrower edge into the seam between the top of the concrete and the shape. Use the shape's inside as a guide and work on Instrument 3. Use the edging tool to repeat the above step. Use light pressure on the instrument this time and generate an even, chamfered surface. Allow the concrete to heal for two hours or until the surface finish is affected by a light swipe with the steel trowel.

4. Pull the rocks out of the stakes of the shape using a hammer's claw end. Take the stakes up. Tap one end of the shape with the hammer several times to rel

Chamfer Edge making procedure 1. Allow the concrete to heal until any ground water is dissipated. This usually requires about 20 to 30 minutes after a wooden float is poured into the concrete and trowled.

2. Start by chamfering the edges of the porch with the edging tool to embed any gravel below the finished surface. Grip the handle of the instrument and insert the narrower edge into the seam between the top of the concrete and the shape. Use the shape's inside as a guide and work on Instrument 3. Use the edging tool to repeat the above step. Use light pressure on the instrument this time and generate an even, chamfered surface. Allow the concrete to heal for two hours or until the surface finish is affected by a light swipe with the steel trowel.

4. Pull the rocks out of the stakes of the shape using a hammer's claw end. Take the stakes up. Tap one end of the shape with the hammer several times to rel

4. Pull the nails out of the form stakes, using the claw end of a hammer. Pull up the stakes. Tap one end of the form several times with the hammer to release it from the edge of the concrete porch. Slide the form one way and lift it up at the same time to remove it without damaging the face or edge of the porch.

5. Put fresh water in a bucket of 5 gallons. Dip into the water a rubber float used to finish plaster. Use the float with tiny, radius strokes to complete the porch wall where the shape was removed. Start the bottom chamfered edge of each stroke and work downwards. Frequently dip the float into the water for the highest outcomes.

Comparison between Fillet Edges and Chamfer

| Chamfer | Fillet | |

| CostLess costly when the part is manually machined | If the part is being milled, the cost will be equal to that of a chamfer | |

| Time | It is usually faster to apply a chamfer | Usually less time effective unless a round mill is already being used to mill complex, curved surfaces |

| Tooling | Require less tools. | Fillets require specific size tools to produce different fillet sizes. |

| Coatings | Due to the sharpness of chamfer corners, paint or protective coatings will draw back from the edge. This means that the coating near the edges will wear more quickly. | For a smooth, even application of the paint or coating, a fillet is a better option. |

No comments:

Post a Comment

Thanks for Comments